It’s no secret that OLED and QLED have battled head-to-head for the past few years for the top spot in display technology. Last week I was one of the few quantum dot representatives at the OLED World Summit 2019 held in San Jose. While I felt a little bit like a fish out of water, it was a welcoming crowd and I learned a lot (and hopefully was able to educate the OLED community as well). Here are 4 of my takeaways from the show:

1. Flexible/Printable OLED is gaining momentum

We all know about the various flexible mobile phones that have been introduced and re-introduced in the past year. You can debate all day long if the impending flexible wave is necessary or not, but the fact remains that there are plenty of electronics companies working on these devices, and plenty of scientists developing new materials to make these devices better/cheaper.

In a future world it would be ideal to print displays like newspapers, on a roll-to-roll (R2R) process on either flexible ultra-thin glass or on plastic. But in order to do this some of the materials are going to have to change. It’s still expensive and wasteful to evaporate OLED materials onto substrates – flexible or not. There were some excellent talks on progress using printable OLED inks. Kateeva is looking at printing OLED devices and quantum dot materials in hopes of leveraging their ink-jet printing platform for next-gen displays. Industrial Technology Research Institute (Taiwan) shared a custom facility with a combination of evaporative steps and printed layers to achieve OLED lighting panels on a R2R process. Professor Choi from KAIST shared some incredible developments in OLEDs and solar cells on fabrics that can withstand washing machine cycles and remain functional (a necessary feature if wearable OLED is really going to take off). An impressive result he also shared was their progress on OLED fibers that can be woven into clothing.

While not present, there were many mentions of the company j-oled which has made fully functional displays (computer monitor sized) in the past using printed OLED materials. Fully printed OLED displays of this type would cause a paradigm shift in the OLED supply chain and manufacturing.

2. Blue is a bottleneck

For materials to emit blue light, energy needs to be pumped into the material at higher levels than for red and green (blue wavelengths are higher energy than other visible colors). This means that not only does the emissive material need to change, but the adjacent materials as well. It’s not trivial to make a blue emitting OLED of the proper color, and even less trivial to make them efficient and long lasting. Both Cynora and Kyulux shared their strategies and struggles with producing the right blue with appropriate stability for commercial applications. In the end, something has to give – color, efficiency, or lifetime. The trifecta is still a challenge to realize.

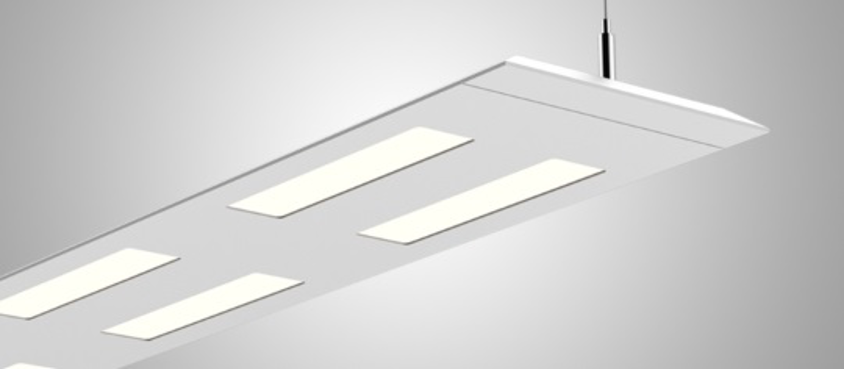

3. OLED Lighting is still looking for the “killer app”

It was amazing to see all of the design concepts for OLED lights in offices, airplanes, cars, even on clothes. OLEDWorks and Acuity shared the spotlight for one presentation showing some unique designs and spaces where OLED lighting could really make an impact. The differentiation here was the design, light uniformity, and aesthetics of the fixture. It is tough to make a case for OLED lighting specs to beat LEDs in many categories, so the highlights tend to be the novel designs enabled by OLED. In one implementation they combine LED up lighting with OLED down lighting, presumably to capitalize on the design freedom of OLEDs and mature technology and efficiency of LEDs. While these lighting products look impressive, they remain niche products, in part due to the continued decline in the cost of LEDs.

Thanks as always for reading!

This article originally appeared on DisplayDaily.